The Workshop

The Workshop

And this, a very simple block room with overhang, became the birthplace of the Dibble workshop.

The Workshop

Early in his career, Paul created art in a range of temporary spaces – community studios, classrooms out of hours, the sleepout in the garden, a corner of the garage. These were all make-shift spaces. The first time he had a studio of his own was a few years after he had married Fran. Fran was pregnant with the couple’s first child – soon their combined family would number six. They went looking for a house in Palmerston North. This was to be a fresh start, with room for the family to grow and thrive. They found an old colonial house, dated around 1904. It had been built by the town’s first engineer, Mr Jickell. This large house and garden suited the Dibble family well. It was large enough to fit them all with gardens to play in. There was a successful treehouse installed in a plum tree, and a chicken coop positioned in a back corner. They renovated to create something that reflected the family they had become.

Most importantly, the house had a large garage. Paul’s first decision was to move the driveway to the opposite side, so no one could ever get a car into the garage. This very simple block room became the birthplace of the Dibble workshop. Some weathered chairs and a couch were moved in, so that he could relax, draw and model, and contemplate away from the busyness of the house. It had large windows on one side, with a view of a large orange tree. There was an overhang, which allowed for work to spill outside once things got going.

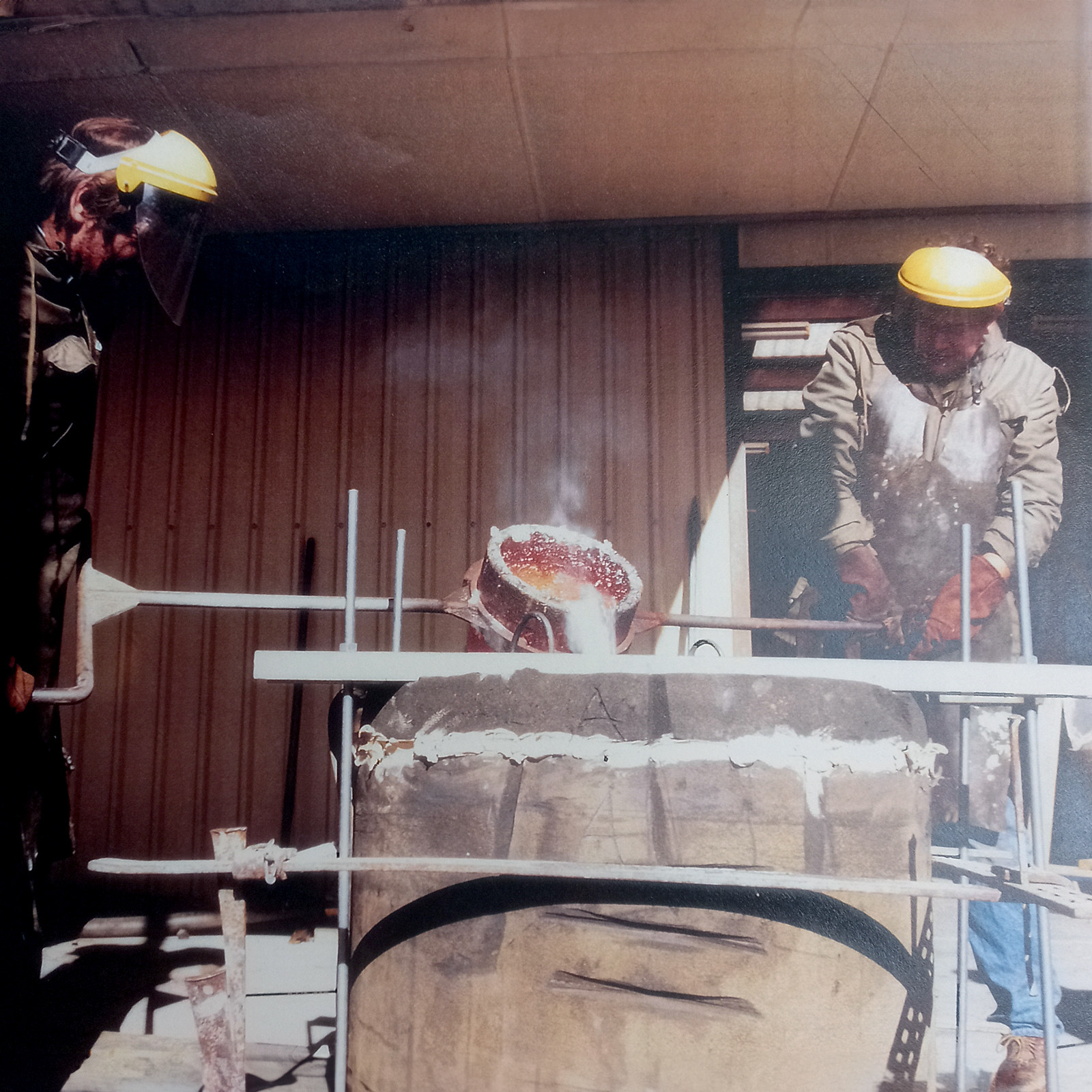

The workshop developed as Paul made works and developed new skills and techniques. It went from a place of contemplation to one of activity and action. Racks and shelves were added for storing plaster moulds. A sand mixer was added to allow him to create preliminary sand moulds. A furnace was moved out on to a brick courtyard. It was covered to stop water from getting into the crucible. Then a tig welder was added. This required a madly thick three phase electrical cable to be laid into the domestic plot. Initially, people came in to help. Later, Dibble workshop took on formal employees. The Dibble children got roped in at times. Son Daniel often got the job of scraping slag while Paul and Fran held the shanks to pour the heated bronze. Large trucks were unable to get up the driveway, so deliveries had to be unloaded by hand, running back and forth moving bags of sand and plaster or a few ingots of bronze each trip. It was a basic affair.

To begin with, this space was used for patternmaking, creating templates to cast from. Finding the right people to cast was an on-going challenge. It proved irritating and costly, so the Dibbles made the decision to complete this work themselves. The couple trialled methods from Paul’s student days. Fran took up a manual job at the Contemporary Art Foundry in Feilding three mornings a week. Her wages there only covered the petrol to get to the job, but it was training. Through it, she learnt enough that they could set up their own shelling system. There was a great deal of trial and error. Some weekends nothing was achieved, except to pour bronze into moulds that collapsed and took days to clean up. But lessons were learned. The first successful castings from the workshop were pieces of the work Pacific Monarch, 1992. This large work is located outside of Te Manawa Gallery. The Dibble workshop cast the feet and hands, the face, and the headdress of leaves.

Space soon became an issue. The home foundry had outgrown itself. Yet, the Dibbles had an earnest desire to keep their work at home. By dovetailing foundry work into domestic life, so much was able to be achieved. The immersive atmosphere of children around their parents while they worked was a set-up they wanted to retain. But with the constraints of space, foundry work was increasingly spilling out into an overhang outside the old garage, making many tasks weather dependant.

The solution to this came when the house next door was put on the market. They kibbled together funds for a deposit, and bought it. It had a garage that was adjacent to the existing workshop. This was fenced off, and the house was rented. The two garages were joined together with a rough framed hallway, which became known as ‘the Chunnel’. The new space became an area for waxwork and mould-making, leaving the metalwork and pouring to the original workshop. This arrangement was to be short-lived. A neighbour had an ongoing complaint, and under the new resource management act, this proved enough to shut the studio down. The Dibbles sold the house they were living in, jumped the fence, and once again started renovating.

With the new workshop, a whole new range of possibilities began.

The business was relocated to a rented site, in a complex shared with the food firm Ernest Adams. There, the smell of the furnace chemicals for the sand moulds cheerfully mingled with the scent of cooking cakes. For a couple of years, this arrangement was successful, but then new owners decided they wanted the art business off the site. Although there was a lease, the crusade to move the Dibble studio on began, going as far as digging up the concrete directly in front of the workshop, making accessibility an issue. Time was up. With a few shopping excursions (and real estate agents who seemed unable to comprehend exactly what the workshop did), a building was purchased in the industrial area of Palmerston North in 2000.

The new workshop opened up a whole new range of possibilities. There was space aplenty. Working away from home had been a concern, with the difficulties of looking after children and domestic tasks. Now the children were older, and the reality was that it made life far easier. Work could be apportioned to its own place and time. Paul and Fran were both full time at the workshop, and it was simpler and less of a load to juggle.

The business grew. The space had a high stud, so bigger works could be developed. It also had a generous mezzanine floor for storage. They created a ‘mould library’ complete with referencing index cards. Hoists and forklifts could be used to allow a larger scale of work. A larger furnace which could pour 240 kg at a time was installed. This was an upgrade from the previous hand-based system, which could only manage 60 kg at a time. The new furnace came from an engineering workshop that made steam trains in Thames.

This workshop continues to be the site of Dibble Art Company. Over the years, it has been refined. A raft of techniques have been created and adapted that suited the designs that Paul was making. As such, it allowed for a dual evolution of each feeding the other – new techniques allowing for new ideas to be discovered, and new ideas creating a need for new methods to be developed.

At one stage, the Dibbles set up a workshop in Auckland, but it never really got going. Paul always felt connected to Auckland, and he believed he might return there one day. Auckland had the sea on the doorstep and a richer variety of culture to explore – though a listlessness took hold if he stayed for too long, out of reach of the workshop. Various ideas were explored: a total move, a studio at both sites with a manager at the Palmerston North site, using the Auckland space to develop ideas and new works that could be then shipped down for casting.

Auckland was a more crowded city, with seemingly endless regulations. This perpetually created obstacles to the studio plans. Nevertheless, the Dibbles made a great number of contacts, and overcame many issues. They shipped an electric furnace from Germany to get around issues of diesel fumes at the inner-city site. Furnishing the workshop proved far more extensive than expected – the Palmerston North site had been developed over a 20-year period. For all this, Auckland brought some success. Four or five pourings were made, and many technical issues were resolved.

But the problems of working back and forth slowed the project. The Dibbles found they were unable to leave Palmerston North for too long, or things tended to get off track. Frustrated at trying to set up in Auckland, with difficulties at each turn, the success of the new site looked unlikely. What finally finished it off was the lockdown from Covid-19 in 2020. It was untenable to have a workshop that could not be accessed. In a brief period between shutdowns, the building was gutted, and the equipment was sent down to Palmerston North.